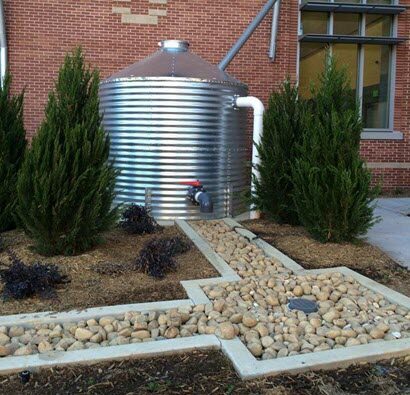

Corrugated Steel Cisterns

Above Ground, Corrugated Steel

Benefits of Above-Ground Tanks

- Cost - Above ground tanks cost approximately 40% less than below ground tanks. Especially in areas of Georgia with rocky soil or high water table, above ground tanks are worth extra consideration. Cost savings are due to:

a. Reduced Shipping Costs

b. Reduced Material Handling Costs - carried by hand or skid-steer on the jobsite, not a crane.

c. Reduced Sitework - pouring a concrete foundation vs. excavating.

2.Maintenance - With a properly functioning prefilter, neither tank requires much maintenance. Maybe every few years. In the past, both above and below ground tanks required confined space safety procedures. However, access hatches allowing egress through the liners are the next technological breakthrough for these tanks.

3.Pumping - With positive suction pressure, pumps run smoother and more efficiently. Pumps can be located inside a mechanical room, safe from the environment and eliminating the need to run high voltage electricity outdoors.

4.We should not neglect the publicity aspect of above-ground tanks. Those that want to spend the extra money on green initiatives often want their neighbors to know. For businesses, it's good business to subtly let your customers know that you care about the earth.

5.Steel tanks have a certain look, that matches the design of many modern buildings. For buildings with a brick or stone veneer, that look can be extended to the tank.

Challenges of Above-Ground Tanks

- Freeze Protection - The biggest challenge with freeze protection is not the tank itself, but any piping with sitting water. The current generation of tanks solved that problem for the most part, with piping penetrations inside the tank. The mass of water in the tank will freeze on the surface, but it will not damage the tank. Freeze protection in Georgia can be accomplished with smart recirculation, keeping initial costs low.

- Aesthetics - The Great Debate among engineers: are the tanks something to hide or something to show?. With a tank such as this in full view of passersby and customers, people will certainly know that the business owner is collecting rainwater. As described in this Freakanomics article, that might be very desirable indeed. By far the most common visual option is unpainted galvanized steel. Epoxy coating and urethane mastic is available. For a different look, the exterior can be clad in wooden planks to simulate staves, or stone or brick.

- Space - The best tactic for maximizing space is to size the tank for the usage, not expected rainfall. This also reduces the cost of the project.

Corgal – 1800 - 300,000 Gallons

Corgal tanks are superior in quality, and GWT provides the best service in the industry. Corgal helped created the corrugated metal tank industry, and has the largest installed base and product offering. Standard roof types include 30°, 10°, Flat, Flat Corrugated, and Inverted. Corgal also engineers and manufacturers tank towers, signs, pump rooms and other buildings. Each job is engineered and manufactured "one of a kind, one at a time."

Timber Tanks America

TimberTanks are round wood storage tanks and for containment of other liquids and some solid materials. TimberTanks wood tanks are also used for signage, bulk storage and enclosures. TimberTanks water storage tanks combine the ageless beauty of wood with the durability of galvanized steel roofs and the modern technology of flexible membrane liners for water containment. The TimberTank structure consists of a wood stave barrel bound with galvanized wire rope wrapped around the barrel to complete the structure. The galvanized steel roof incorporates factory formed and punched high-rib roof panels which bolt together to create a weatherproof roof structure. Water containment is achieved with geotextile preliners installed within the wood barrel and a factory welded seam flexible membrane liner suspended inside the tank.

Texas Metal Tanks

Georgia Water Tanks keeps an inventory of Texas Metal Tanks, 300 - 500 gallon sizes. Texas Metal Tanks manufactures both traditional galvanized steel cisterns and stainless steel cisterns. The galvanized steel tanks are G-90 grade 20 gauge metal made in the USA. We do not import foreign steel. The top is 22 gauge. After the tank is constructed, a paint / epoxy lining is applied to the interior of the tank to provide a protective barrier between the water and the metal itself. This product is FDA approved for potable (drinking) water applications and is ANSI / NSF 61 certified. Each tank is tested at the factory to ensure that it is watertight. With almost 90 years of history, these tanks have a typical lifespan of 30 - 35 years. Galvanized tanks have a one-year warranty.

Ready to design? Click Here